Unlocking Innovation Through Rapid Prototype: A Game Changer for Metal Fabricators

Understanding Rapid Prototyping

In today's fast-paced industrial environment, businesses demand not only efficiency but also innovation. One method that has emerged as a vital tool in meeting these demands is rapid prototype technology. This approach allows manufacturers and metal fabricators to create physical models of their products swiftly and accurately. Through a streamlined process, rapid prototyping enables companies to test concepts, refine designs, and ultimately reduce time-to-market.

The Process of Rapid Prototyping

The rapid prototype process can be broken down into several key phases:

- Concept Development: The initial phase involves brainstorming and sketching ideas based on product requirements.

- 3D Modeling: Designers convert sketches into digital 3D models using sophisticated software.

- Material Selection: Choosing appropriate materials is crucial as it impacts the prototype’s authenticity.

- Prototyping Technique: Different techniques such as 3D printing, CNC machining, and injection molding can be employed.

- Iterative Testing: Each prototype undergoes testing, offering opportunities for modifications and improvements.

- Final Production: Once the design is optimized, the product can be mass-produced efficiently.

Benefits of Rapid Prototyping in Metal Fabrication

The implications of rapid prototype technology for metal fabricators are vast and transformative. Here are some benefits that stand out:

- Speed: Rapid prototyping significantly cuts down the time from design to production. This agility allows businesses to respond to market changes faster.

- Cost-Effectiveness: By identifying design flaws early through prototypes, companies can avoid expensive production overruns.

- Improved Accuracy: Advanced technologies ensure that prototypes closely match the intended final product, leading to higher quality outcomes.

- Enhanced Collaboration: Prototypes facilitate better communication among team members and stakeholders, ensuring everyone is aligned on the product's vision.

- Greater Innovation: The iterative nature of rapid prototyping encourages experimentation, allowing designers to explore unconventional solutions.

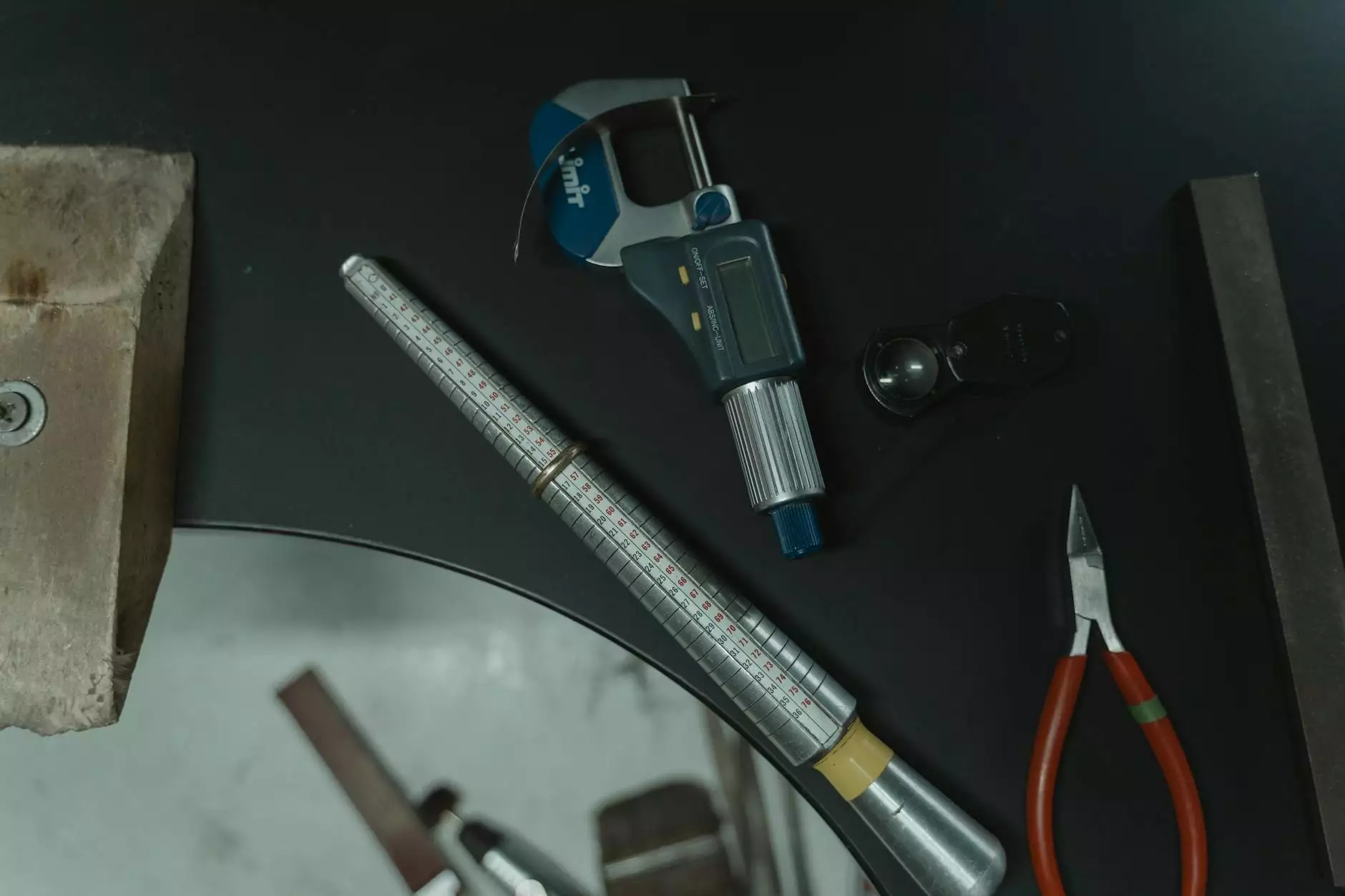

Key Technologies in Rapid Prototyping

Several technologies have paved the way for effective rapid prototype development, including:

- 3D Printing: This method constructs objects layer by layer using materials like plastic, resin, or metal. It’s revolutionizing how prototypes are made, especially in small batches.

- CNC Machining: Computer Numerical Control machining allows for precision cutting of materials, resulting in highly accurate prototypes.

- Laser Sintering: This technique uses lasers to fuse materials together, creating complex geometries unachievable with traditional methods.

- Injection Molding: A widely used technique for mass production of parts, it allows prototypes to be created before full production starts.

Applications of Rapid Prototyping in Metal Fabrication

In the realm of metal fabrication, rapid prototype techniques are applied in various sectors, including:

- Aerospace: In aerospace engineering, prototypes are critical for testing aerodynamics and material performance under different conditions.

- Automotive: Automotive manufacturers use rapid prototyping for both conceptual models and functional parts, leading to increased vehicle efficiency.

- Medical Devices: The medical field benefits immensely from rapid prototyping, as it allows for the swift development of complex surgical instruments and implants.

- Consumer Electronics: Rapid prototyping enables tech companies to iterate quickly on designs, leading to innovative gadgets that meet consumer needs.

- Industrial Equipment: Customized machinery and tools can be rapidly prototyped, ensuring compatibility with specific operational requirements.

Challenges in Rapid Prototyping

While there are numerous advantages, it is also essential to be aware of potential challenges associated with rapid prototype technology:

- Material Limitations: Not all materials are suitable for every type of prototyping, and the choice of material can affect functionality.

- Initial Costs: The investment in rapid prototyping technology and machinery can be substantial, which may be a barrier for smaller businesses.

- Skill Requirements: Adequate training and skills are necessary to operate complex prototyping machines and software, necessitating ongoing education.

- Intellectual Property Risks: Rapid prototyping could potentially expose companies to IP theft or infringement if designs are not protected properly.

Future Trends in Rapid Prototyping

The future of rapid prototype technology is bright, with several trends on the horizon that will shape the landscape:

- Integration of AI: Artificial intelligence is increasingly being utilized to streamline the design process and improve accuracy in prototyping.

- Biofabrication: Advances in bio-materials are opening new avenues for rapid prototyping in the medical and environmental sectors.

- Sustainability Initiatives: As industries move towards greener practices, eco-friendly materials and processes are being developed for prototypes.

- Mass Customization: The demand for personalized products is expected to grow, pushing rapid prototyping into new realms of industrial production.

Why Choose DeepMould.net for Your Rapid Prototyping Needs

At DeepMould.net, we specialize in providing high-quality rapid prototyping services tailored for the metal fabrication industry. Our expertise lies in:

- State-of-the-Art Technology: We leverage the latest prototyping technologies to deliver precision and quality.

- Experienced Professionals: Our team consists of skilled engineers and designers with years of experience in the metal fabrication industry.

- Commitment to Quality: We adhere to strict quality control measures, ensuring every prototype meets your specifications.

- Timely Delivery: Understanding the importance of time-to-market, we prioritize swift turnaround times without compromising quality.

Conclusion

In conclusion, rapid prototype technology is transforming the journey from concept to realization across various industries, particularly in metal fabrication. Its ability to enhance innovation, improve quality, and reduce costs is invaluable for businesses aiming to stay competitive in an ever-evolving market. Partnering with experts like DeepMould.net ensures you harness the full potential of rapid prototyping, enabling you to bring your visions to life with speed and precision.